DESIGNER OF

TECHNICAL PROCEDURES

FOR THE METALWORKING INDUSTRY

AND THE STEEL INDUSTRY

OUR THERMICS ACTIVITY

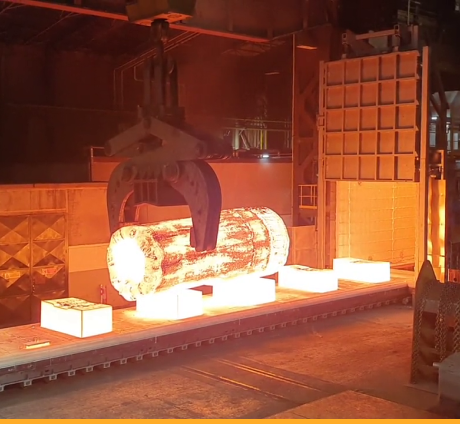

Highly experiencedin different heating processes, the CLEIA teams (formerly CERIC TECHNOLOGIE) have developed innovative heating procedures for the metalworking industry for many years.

They use high-capacity kilns used to forge or process metals such as steel, aluminium or copper.

These are new and they save more energy (hybrid or 100% electrical gas)

We design and construct turnkey assemblies including kiln masonry, mechanisation, thermal equipment, automation and monitoring.

We deliver production lines for metalworking industries all over the world.

mission

REDUCING ENERGY CONSUMPTION

CUSTOMISED SOLUTIONS

REDUCING CO2 AND NOX EMISSIONS

CUSTOMISED ENGINEERING

TYPES OF PROJECTS

Thermal procedures for the metalworking

industry and the steel industry

Heating process using forging, reheating,

thermal processing, stabilisation, homogenisation,

calibration of powders and oxides

Gas/electricity standardisation

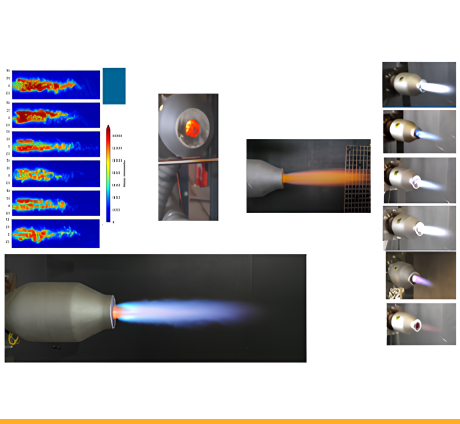

Retrofit burners (eco-energy)

Regenerative and self-regenerative

self-recuperative burners

Transition to syngas, hydrogen,

alternative energies

WHAT WE OFFER

YOUR PRODUCTS

STEELS

ALLOYED STEELS

STAINLESS STEELS

OTHER ALLOYS

THERMICS

solutions

ROTARY HEARTH KILNS

BOGIE HEARTH KILNS

STILL HEARTH KILNS

TOP-HAT KILNS

PILGRIM STEP KILNS

QUENCHING KILNS

ANNEALING OVENS

TEMPERING FURNACES

SPECIAL BURNERS

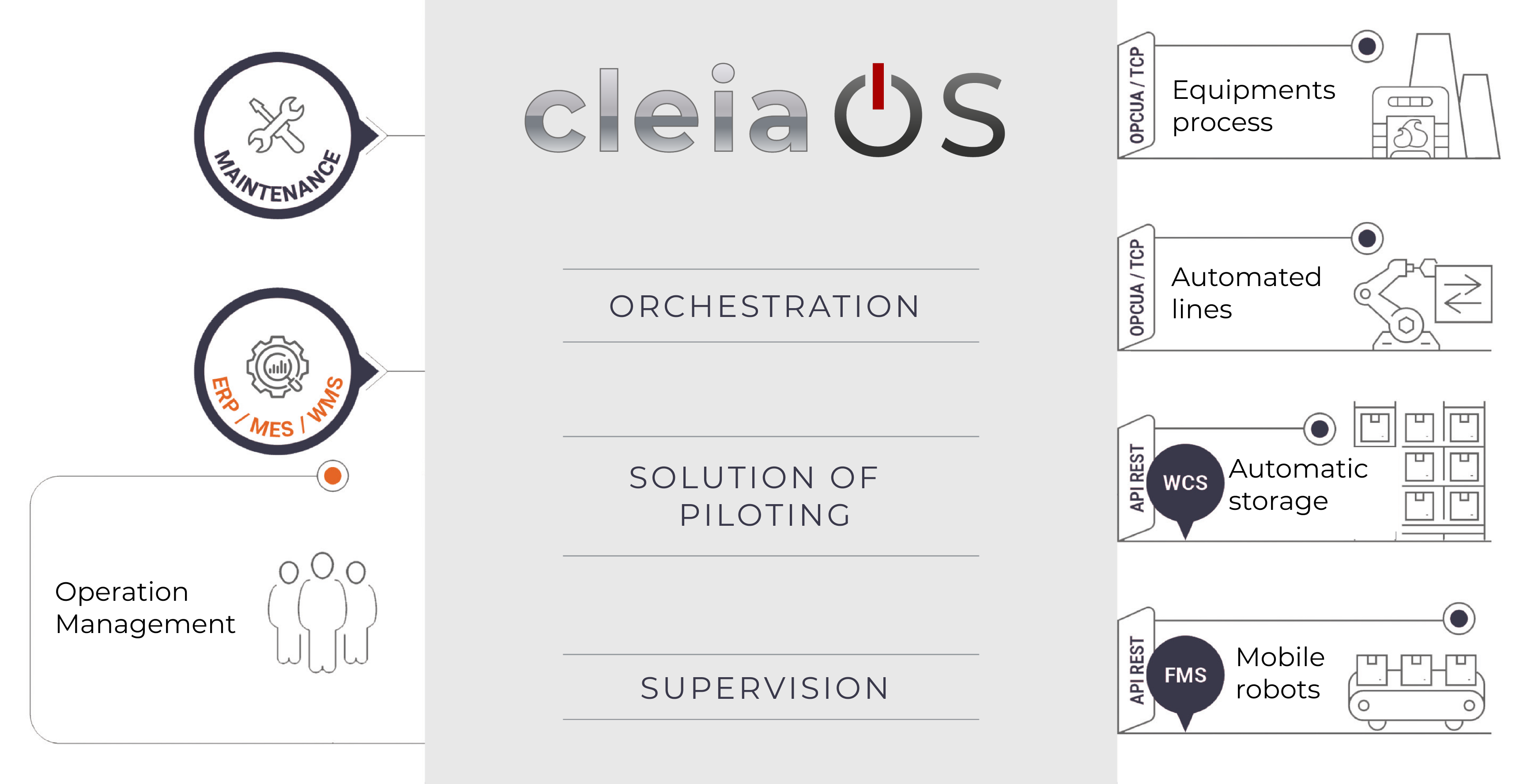

CLEIAOS, THE ORCHESTRATOR OF YOUR PRODUCTION

The advantages of cleiaOS

Explanation illustration of our cleiaOS production line orchestrator

cleiaOS offers key intuitive orchestration, optimised maintenance and global supervision functionalities, all with a no-code approach, thus facilitating the deployment and adaptation of the system.

With cleiaOS, our industrial IT solutions offer complete visibility of the operations, enabling better planning, real time monitoring and effective decision-making.

This allows for connected, reactive and quality-orientated plant management.

PARTNERS

BRANCHES

The Thermics activity perfectly illustrates CLEIA’s ability to adapt and expand its expertise to new industrial challenges. By combining our historic know-how with a constant willingness to be innovative, we are ready to meet the thermal industry’s current and future needs while contributing towards a more sustainable future.

AND AFTERWARDS?

Our ability to provide you with a complete after-sales service which covers many technical skills and has great reactivity, is one of CLEIA’s biggest strengths.